SPS Capabilities

Open-Loop Plastic Recyling

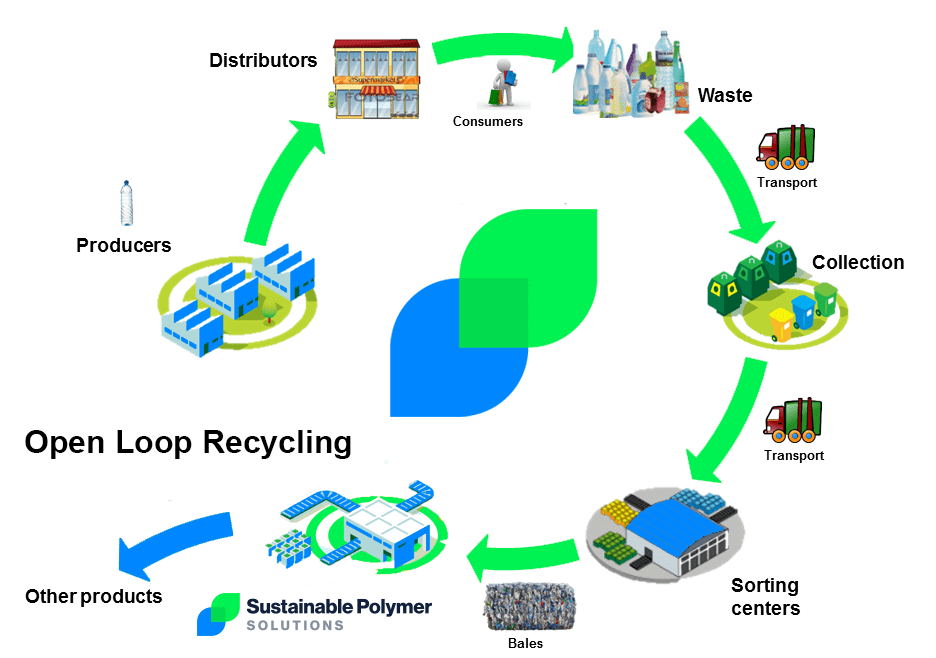

Open-Loop Recycling

Sustainable Polymer Solutions is an expert at open-loop recycling, the conversion of material from one or more products into a new product, such as recycling automotive parts into consumer products or construction components. We identify overlooked and underutilized plastic waste and are creating many more viable options for manufacturing use.

SPS is dedicated to and working towards continuous feed streams to provide customers with reliable, consistent, and cost-effective recycled resins. We’re committed to being a trusted supplier contributing to your long-term business success.

The SPS Process

Sort & Clean

⇓

Processes Used:

- Wash Line

- Sink Float

Grind

⇓

Sell or Enhance:

- Sell as Regrind

- Enhance / Custom Components

Process

⇓

Pelletize:

-

Used In

- Injection Molding

- Blow Molding

- Extrusion Molding

- Blending

Pulverized:

Used In

- Rotational Molding

- Color Concentrate Manufacturing

- Fluidizing Bed Powder Coating

- Powder Coating

Testing

Testing occurs with incoming waste streams to ensure they are not cross-contaminated, as well as, post-processing to ensure the recycled resin meets our customer’s specifications.

Pelletized Plastics

Recycling plastic by pelletizing is one of the best ways to reuse and repurpose plastic scraps that are produced in high quality from manufacturing plants. Plastic manufacturing companies can then re-use these pelletized plastics in a wide variety of applications.

The process used by Sustainable Polymer Solutions for plastic pelletizing returns the full value of the recycled materials to the manufacturer. These recycled resin pellets are ideal for re-use in high-end applications for the automotive and consumer markets.

Sustainable Polymer Solutions offers toll processing for those who want to re-use scrap in their own manufacturing processes. Contact us to discuss how SPS can help reduce your manufacturing costs through toll recycling.

Compound Components

Plastic compounding is a process of melt blending plastics with other additives which changes the plastic’s physical property performance, thermal, electrical, or aesthetic characteristics. The heating process along with mechanical mixing creates a chemical interaction that transforms the blend into a new compound component.

Compound components are often used when a molded product needs a cost-effective way to enhance performance or impact strength over other commercially available grades. Plastic compounding also allows manufacturers to tailor the resin to exact specifications and part requirements.

Our team at Sustainable Polymer Solutions is available to help customize a compact component from recycled plastic. If you prefer a virgin plastic component engineered, our sister company, PolyEvo, has the solution.

Pulverized Plastics

Pulverized plastics can help reduce material costs, recover value, and improve product quality in the manufacturing process.

Finely milled pulverized plastics are used on compression molding, highly reinforced composites, powder coating, 3D printing, and other demanding applications. For compression molding, the powder can be used neat or blended with lubricants, modifiers, additives, and/or reinforcements prior to being molded into basic shapes that have no internal stresses.